NEMA Motors

How can you ensure that an electric motor offers absolute performance, efficiency, and interchangeability in the North American market and other international markets that adopt specific standards? The answer lies in adopting a rigorous and universally recognized classification system, designed to eliminate any ambiguity and ensure maximum operational reliability.

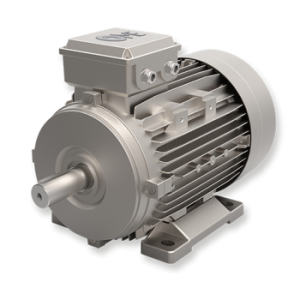

In this context, NEMA motors represent the definitive solution. Designed and built in compliance with the directives of the National Electrical Manufacturers Association (NEMA) in the United States, these motors are not just components but a guarantee of compatibility, performance, and durability. Choosing a NEMA motor means relying on a product whose mechanical and electrical characteristics are precisely defined, facilitating design, installation, and maintenance in any industrial application, from the United States to South America.

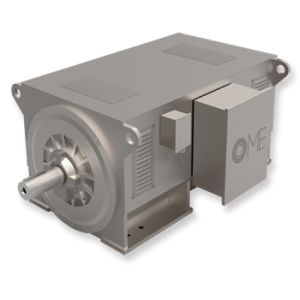

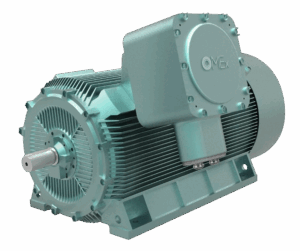

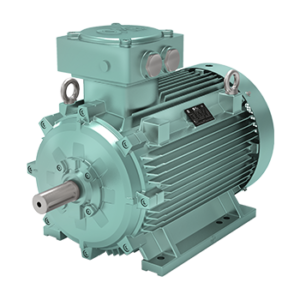

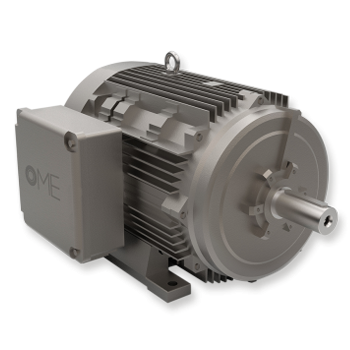

OME Motors, with its extensive experience in producing Made in Italy electric motors, offers a complete range of motors that comply with NEMA electric motor standards, combining Italian manufacturing quality with the specifications required by the most demanding international markets. Our motors are designed to exceed expectations in terms of energy efficiency, robustness, and versatility, positioning themselves as the ideal choice for machinery manufacturers, system integrators, and end-users who accept no compromises.

How to choose the ideal NEMA Motors for your applications

Choosing the correct electric motor is a crucial step that directly impacts machinery efficiency, operating costs, and long-term reliability. To confidently navigate the world of NEMA electric motors, it is essential to analyze a series of technical and application parameters. Carefully evaluating the NEMA specifications for electric motors is not just a matter of compliance but a strategy to optimize investment. Here are the key factors to consider:

- Power and Torque Requirements: Precisely define the power (HP or kW) and the starting and running torque needed for your application. This will determine the most suitable size and design class (e.g., NEMA design b electric motors).

- Frame Size: The standard electric motor NEMA frame uniquely defines the physical dimensions of the motor. This standardization ensures complete interchangeability between motors from different manufacturers, simplifying replacement and maintenance.

- Energy Efficiency: Opting for a NEMA premium efficiency electric motor is a strategic choice. Compliant with the EISA (Energy Independence and Security Act) standard, these motors significantly reduce energy consumption, ensuring a quick return on investment and a lower environmental impact.

- Supply Voltage and Frequency: Verify compatibility with the local electrical grid. Our motors are available for standard American market voltages (e.g., 230/460V, 575V) and for frequencies of 50 Hz and 60 Hz, ensuring maximum flexibility.

- Operating Environment and IP Protection Rating: The environment determines the necessary degree of protection. We offer solutions such as the IP23 NEMA asynchronous electric motor for protected environments or the IP55 NEMA asynchronous electric motor for more demanding applications.

- Inverter Compatibility: If the application requires variable speed control, it is essential to choose an “inverter-duty” motor, designed to withstand the electrical stresses imposed by frequency converters. Our range of NEMA motors is fully compatible with the latest inverters.

Types of OME NEMA Motors: Solutions for every industrial need

The OME Motors NEMA electric motor range is designed to cover a vast spectrum of industrial applications, always offering the most performant and reliable solution.

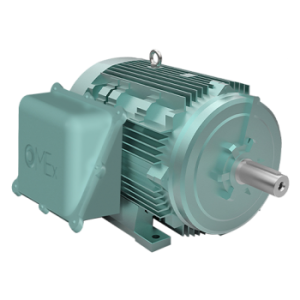

NEMA Design B motors:the standard for versatility and performance

The NEMA design b electric motors represents the most common and versatile category of three-phase asynchronous motors. They are characterized by normal starting torque, low starting current, and a nominal slip of less than 5%. These characteristics make them the ideal choice for the vast majority of industrial applications (centrifugal pumps, fans, compressors, and conveyor belts).

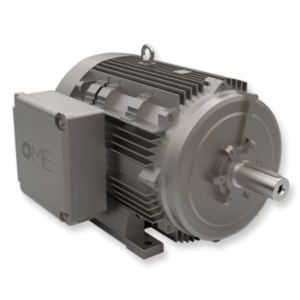

NEMA Premium efficiency motors: maximizing energy savings

NEMA premium efficiency electric motors meet and exceed the minimum efficiency requirements imposed by EISA regulations, ensuring a significantly lower TCO (Total Cost of Ownership) compared to standard motors. The initial investment is quickly recouped thanks to lower electricity consumption.

NEMA Motors with IP23 and IP55 protection: the answer for every environment

The durability of an electric motor depends on its ability to withstand external agents.

- An IP23 NEMA asynchronous electric motor is designed for installations in clean and dry indoor environments.

- An IP55 NEMA asynchronous electric motor ensures superior protection for more severe applications (exposed to dust and water splashes).

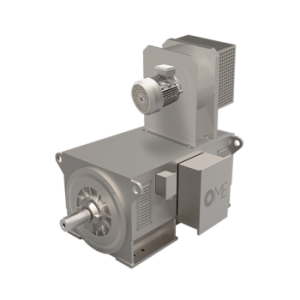

NEMA and above electric motors: customized solutions

The NEMA and above electric motors category represents our commitment to exceeding standard specifications. Our strength lies in our ability to develop custom-built solutions to meet the unique needs of our customers, whether for mechanical modifications, special windings, or integrated sensors.

Understanding the standards: what defines NEMA Electric Motor standards

The NEMA standards for electric motors constitute a common technical language that guarantees the safety and efficiency of rotating machinery.

The meaning of NEMA electric motor codes

The NEMA electric motor codes, identified by a letter, define the torque and starting current characteristics:

- Design A: Similar to Design B but with a higher starting current.

- Design C: Characterized by a high starting torque, ideal for full-load starts (e.g., piston compressors or heavy conveyor belts).

- Design D: Offers exceptionally high starting torque and high slip, suitable for intermittent high-impact applications (e.g., presses and metalworking machinery).

Decoding the electric Motor NEMA frame

The NEMA frame designation system is powerful. The number identifying the frame (e.g., “143T” or “254T”) is based on physical dimensions. This rigorous coding ensures that a NEMA motor of a certain size can be replaced with another of the same size, regardless of the manufacturer, without the need for mechanical modifications.

The NEMA standard for electric motors: a global reference

Although originating in the United States, the NEMA standard for electric motors is now a benchmark throughout the Americas and in many other regions. For those exporting machinery to these areas, using NEMA electric motors is often an essential requirement.

Why choose OME Motors NEMA motors?

Choosing OME Motors for the supply of NEMA electric motors means choosing a technological partner that combines the excellence of Made in Italy with deep knowledge of international standards.

- Our motors are designed to excel in terms of reliability, efficiency, and durability.

- The cast iron body construction provides superior mechanical robustness, reducing vibrations and noise.

- We guarantee consistent performance and minimize maintenance needs through rigorous quality control.

- The modularity of our design and our customization capabilities allow us to offer flexible solutions that perfectly adapt to any specific need.

Choosing OME Motors means having the certainty of a high-quality product, supported by global assistance and a team of experts. Discover all OME Motors’ electric motors and bring Italian efficiency and reliability to the heart of your machinery.

![]()