How is it possible to combine maximum energy efficiency, superior power density, and absolute precision control in a single industrial motor? The answer lies in a technology that is redefining performance and sustainability standards in the sector: the

permanent magnet motor. In an industrial context where optimizing operating costs (TCO) and reducing environmental impact have become strategic priorities, adopting advanced motor solutions is no longer an option, but a competitive necessity.

Permanent magnet synchronous motors represent the pinnacle of modern motor engineering. Unlike traditional induction motors, these devices eliminate electrical losses in the rotor thanks to the use of high-energy magnets, ensuring ultra-premium efficiency (higher than IE4 class) and lower operating temperatures. This directly translates into lower energy consumption, greater reliability, and an extended lifespan, offering a rapid and measurable return on investment.

OME Motors, with its “Made in Italy” expertise and rigorous quality control, designs and produces a comprehensive range of

permanent magnet motors to meet the most demanding application challenges.

Choosing the permanent magnet electric motor: a guide to fundamental criteria

Selecting the ideal motor for a specific industrial application requires careful analysis of technical and operational factors. Understanding the key variables is the first step to maximizing efficiency:

- Operating Regime: Does the application require a fixed speed or continuous adjustment? This is the fundamental distinction between a motor optimized for direct start-up and a permanent magnet synchronous motor designed to operate in synergy with an inverter (Variable Speed Drive – VSD).

- Efficiency Class: Evaluating permanent magnet synchronous electric motors with Ultra-Premium efficiency (higher than IE4) is a strategic investment that drastically reduces energy costs throughout the motor’s entire lifecycle.

- Torque and Power Density: The interior permanent magnet motor offers exceptional performance with high and constant torque even at low speeds. Furthermore, its high power density allows for more compact and lighter motors with the same performance.

- Specific Application: Analyzing the load profile and environmental conditions is vital to configuring the most suitable 3-phase permanent magnet motor.

- Total Cost of Ownership (TCO): A permanent magnet motor will have a higher initial cost than an induction motor, but the accumulated energy savings and lower maintenance result in a significantly lower TCO.

- Integration and Control: It is essential to ensure full compatibility between the synchronous motor and the drive system (inverter) to guarantee optimal performance.

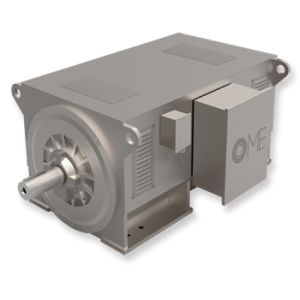

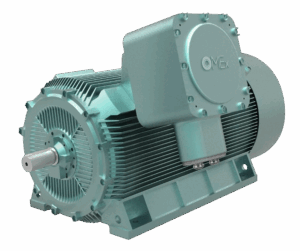

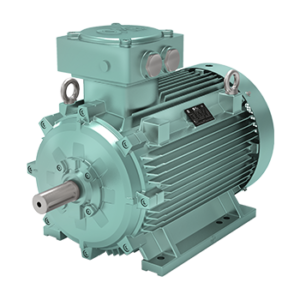

Types of OME Motors permanent magnet motors: the OMPM series

The

OMPM series from OME Motors embodies technological excellence in the field of

permanent magnet synchronous motors. Designed and built in Italy, these motors are available in a wide range of sizes (from H 80 to H 400) and powers (from 0.75 to 2,500 kW).

Permanent magnet AC motor for fixed-speed applications

For applications that operate continuously at a nominal speed, such as standard pumps or fans, the “Fixed Speed” version of our

permanent magnet AC motor offers an unparalleled competitive advantage. Even without the need for an inverter, these motors guarantee efficiency superior to IE4, reducing consumption from the first day of use.

Permanent magnet motor generators for variable speed drives (VSD)

This is the configuration where the technology expresses its maximum potential. Paired with a dedicated inverter, the

high-speed permanent magnet motor from the OMPM series for VSD use offers precise speed control and constant torque. It is the ideal solution for compressors, water treatment systems, and food processing lines. Precise speed control can cut energy consumption by up to 50% compared to traditional solutions. This type of

AC synchronous permanent magnet electric motor is at the heart of Industry 4.0.

Permanent magnet motor vs induction motor: the technological advantage

The key distinction lies in the rotor design. While an induction motor generates the rotor’s magnetic field through currents induced by the stator (resulting in energy losses), a

permanent magnet motor uses high-coercivity magnets mounted directly on the rotor.

This structural difference generates decisive advantages:

- Elimination of rotor losses, leading to Ultra-Premium efficiency levels.

- Higher power density: For the same power, a permanent-magnet electric motor is smaller and lighter.

- Efficiency at partial loads: Efficiency remains exceptionally high even when the motor is not running at full capacity, unlike traditional induction motors.

Applications: where the permanent magnet motor excels

Thanks to their versatility and precision,

AC permanent magnet motor applications cover crucial industrial sectors:

- HVAC and Air Treatment: Precise speed regulation allows for adapting the airflow to instantaneous demand, with enormous energy savings.

- Pumping and Water Treatment: For centrifugal pumps, the use of a three-phase permanent magnet motor with an inverter allows for maintaining constant pressure, eliminating energy waste.

- Compressors: The ability to maintain high torque at various speeds translates into more efficient compressed air production and a reduction in load/unload cycles.

- Transportation and Handling: In conveyor belts and extruders, the precise control and constant torque guarantee a stable and high-quality process.

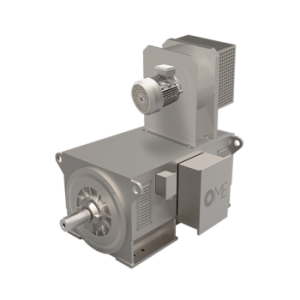

Why choose OME Motors

Choosing an OME Motors

permanent magnet electric motor means relying on a technological partner. Our philosophy is based on “Made in Italy” quality, customization, and performance. We guarantee compliance with the most stringent international standards (UNEL MEC, UL/CSA, GOST).

Our strength is flexibility. We are able to design customized solutions, personalizing the

permanent magnet AC synchronous electric motors to meet specific installation and performance requirements, ranging from standard motors to explosion-proof versions.

Investing in a

permanent magnet motor from OME Motors is a strategic choice to reduce operating costs, increase productivity, and make your plant more sustainable. Discover all

OME Motors electric motors and find the most suitable solution to empower your business.

![]()