Slip ring electric Motors (Wound Rotor Motors)

How is it possible to start extremely heavy and high-inertia industrial loads, such as mills, crushers, or large fans, ensuring maximum starting torque without generating current peaks that are harmful to the electrical grid and the plant’s mechanics? The answer to this engineering challenge lies in a specific and highly performant technology: the slip ring motor, also known as a wound rotor motor or slip ring induction motor.

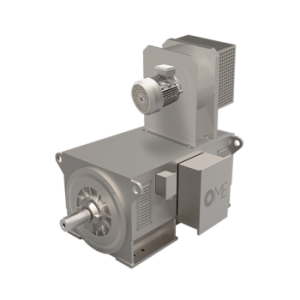

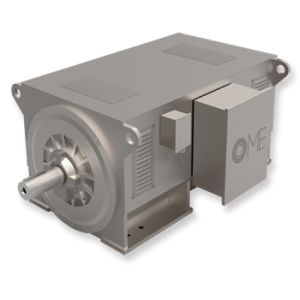

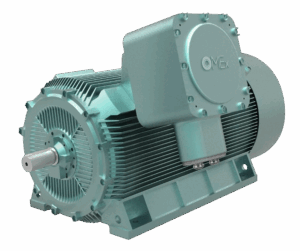

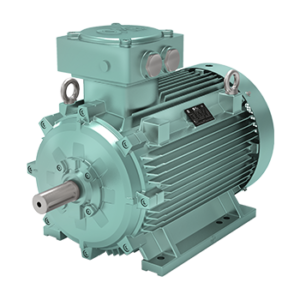

These electric motors represent the excellent solution for the most demanding applications, where traditional squirrel cage motors would show their limitations. Thanks to their unique architecture, which features a rotor with windings accessible from the outside via a slip ring assembly, slip ring motors offer unparalleled control during startup. They allow for the insertion of external resistors into the rotor circuit, drastically limiting the inrush current while maximizing the starting torque from the very first moment. OME Motors designs and manufactures high voltage wound rotor motors that embody the perfect synthesis of power, control, and reliability, ideal for sustaining the beating heart of the most demanding industrial processes.

Wound rotor motors: How to choose the ideal slip ring motor

The selection of an electric motor for heavy-duty applications cannot be left to chance. It’s an analysis that requires the evaluation of multiple technical and operational factors to ensure not only correct operation but also the efficiency, durability, and safety of the entire system. When evaluating a wound rotor slip ring motor, it is essential to consider the specific needs of the application to identify the most performant model. OME Motors offers a wide range of configurations, with frame sizes from H56 up to H710 and powers ranging from 0.18 kW to 2,000 kW, to meet every need. Let’s look at the essential criteria for selection:

- Starting Torque and Load Characteristics: Evaluating the inertia of the load to be moved is the first step. Applications like mills, presses, or extruders require a very high starting torque, an intrinsic characteristic of the slip ring induction motor.

- Speed Control: If the application requires fine speed regulation, especially during starting or at steady state, slip ring motors, often combined with rheostats or inverters, offer superior flexibility.

- Starting Current: In contexts with sensitive electrical grids or to avoid mechanical stress, the ability of an AC slip ring motor to limit the inrush current is a decisive advantage.

- Environmental Conditions and Cooling System: The operating environment (dusty, humid, aggressive) influences the choice of IP rating and cooling system. OME Motors offers efficient solutions like IC 411 (self-ventilated), IC 416 (forced ventilation), and IC 611 (air-to-air heat exchanger), to ensure optimal operating temperatures in all conditions.

- Voltage and Frequency: Our production covers multiple voltages and 50/60 Hz frequencies, ensuring compatibility with international grid standards and maximum design flexibility.

- Energy Efficiency: An efficient motor translates into savings on operating costs. Our motors are designed to optimize consumption, a crucial aspect in the economics of an industrial plant.

The advantages of a 3 Phase slip ring induction motor

The adoption of a 3 phase slip ring induction motor is not just a technical choice but a strategic investment that brings tangible benefits in terms of performance, reliability, and operating costs. The advantages of slip ring induction motor are numerous and are particularly evident in the most severe operating conditions, where other types of motors would not be suitable.

High starting Torque with reduced currents

This is the most significant advantage. The ability to insert variable resistors into the rotor circuit through the motor slip ring allows for modulating the torque/speed curve. During startup, maximum torque can be achieved at nearly zero speed, with an inrush current that can be limited to values slightly higher than the nominal (typically 1.5 – 2.5 times, versus 6-8 times for a squirrel cage motor). This protects both the power supply network from voltage drops and mechanical components (couplings, reducers) from shock and premature wear.

Precise speed and performance control

The same architecture that allows for a smooth start also enables effective speed control. By modifying the rotor resistance, it is possible to vary the motor speed within a certain range, adapting it to the process’s needs. This characteristic makes the 3 phase slip ring motor particularly versatile, and when combined with modern control systems and inverters, it allows for implementing sophisticated operating logics, further optimizing the production cycle and energy consumption.

Structural robustness and “Made in Italy” reliability

An electric motor slip ring signed OME Motors is built to last. The frame, made of welded steel plate, guarantees superior structural rigidity and great resistance to vibrations. The double-layer stator windings undergo a vacuum pressure impregnation (VPI) process, which ensures perfect insulation and exceptional protection against humidity and aggressive agents. The rotor, the heart of the system, is also constructed with the utmost care: the cores are interference-fitted to eliminate vibrations, and the bars, made of copper or copper alloy, are connected via an advanced brazing process that ensures maximum mechanical strength and electrical conductivity. Every motor is the result of the “Made in Italy” approach, with internal quality control performed by specialized technicians at every stage of the production process.

Applications of slip ring induction motor in the most demanding industrial sectors

The versatility and controlled power of slip ring motors make them the preferred choice in numerous industrial sectors where working conditions are extreme and reliability is a non-negotiable requirement. The ability to handle high-inertia loads makes them irreplaceable in many contexts.

- Quarries and Mines: Starting crushers, ball or rod mills, and long conveyor belts loaded with material requires immense torque. Wound rotor motors provide the necessary power in a controlled manner, preventing mechanical stress and interruptions.

- Cement Plants: For moving rotary kilns, vertical mills, and large fans for smoke extraction, a slip ring electric motor ensures a gradual and reliable start, fundamental for the stability of the cement production process.

- Steel Plants: In rolling mills, presses, and other metalworking machines, the ability to control torque and speed is crucial for the quality of the final product and operator safety.

- Pumps and Industrial Ventilation: For large pumping systems, water lifting stations, and ventilation systems for tunnels or mines, a smooth start reduces water hammer in pipelines and stress on impellers.

- Presses and Extruders: In the plastics and rubber sector, extruders and presses require precise torque control to handle materials with different viscosities, a task perfectly accomplished by a motorized slip ring.

- Desalination Plants and Wind Turbines: Even in innovative applications like reverse osmosis plants or as generators in some wind turbine configurations (DFIG), wound rotor slip ring motor technology plays a key role in power and speed control.

Anatomy of an OME Motors Electric slip ring motor

Understanding the technology behind an OME Motorselectric motor means appreciating its quality and superior engineering. Every component is designed and manufactured to contribute to a high-performance and durable assembly, in compliance with European UNEL-MEC standards and the most stringent international quality standards.

The wound rotor and the slip ring assembly

Unlike the squirrel cage rotor, the rotor of a slip ring motor consists of three-phase windings, similar to those of the stator. The terminals of these windings are not short-circuited but are connected to an assembly composed of conductive rings (slip rings) mounted on the motor shaft. Graphite brushes, in contact with the rings, allow the rotor circuit to be connected to an external rheostat. This is the key to varying the total resistance of the rotor and, consequently, controlling its performance during starting and at steady state.

Lubrication systems and bearings

The durability of a motor largely depends on the quality of its bearings and effective lubrication. OME Motors offers various options to meet the most diverse maintenance needs and operating conditions: from traditional grease lubrication to more complex systems like oil ring lubrication or forced oil lubrication, ideal for continuous service and high-speed applications, ensuring extended service life and reducing maintenance interventions.

In summary, choosing an OME Motors slip ring motor means relying on an advanced engineering solution, capable of offering controlled power, maximum reliability, and operational efficiency. The tailored approach, which allows for extensive customization, and the support of an international assistance network, make our offering the ideal answer for those seeking uncompromising performance. The combination of high-quality materials, certified production processes, and engineering focused on real industrial needs positions our motors at the top of the market.

To explore our complete range of electric drive solutions and discover how we can enhance your application, we invite you to consult our catalog. Discover all OME Motors electric motors.

![]()