Technical Choices, Efficiency, and Application of Industrial Fan Motors

The industrial landscape requires specific mechanical and electrical solutions capable of handling high airflows and extreme working conditions. Here are the main types of fan motors and their industrial applications.

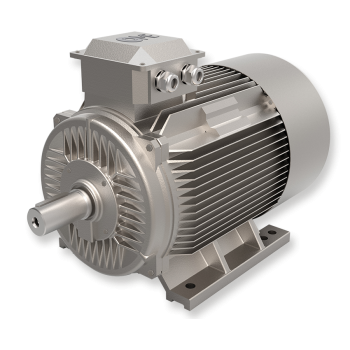

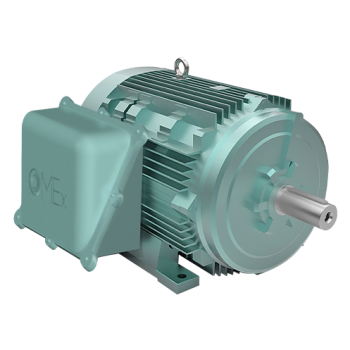

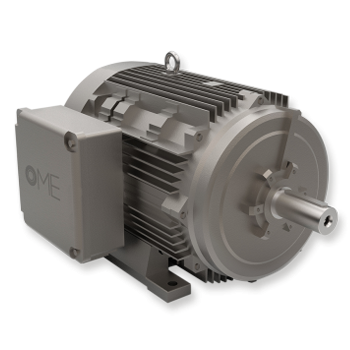

Electric Motors for Industrial Fans

The range of electric motors for fans covers needs that span from cooling control panels and automated machines to the extraction of gases, vapors, and dust in production departments. Some of the primary advantages include:

- Cost savings on energy, thanks to the use of high-efficiency motors and inverters that optimize speed

- Quiet operation and reduced vibrations even at high speeds

- Reliability for continuous working cycles (24/7), essential for industrial processes that do not allow operational breaks

- Compatibility with centralized controls and plant supervision systems (Industry 4.0)

Criteria for Choosing Electric Fan Motors in an Industrial Context

The industrial environment imposes strict criteria that go well beyond nominal power.

It is essential to evaluate:

- IP protection level and resistance to dust, oil, moisture, or chemical vapors

- Construction materials for high temperatures or corrosive environments

- Ease of access for maintenance, disassembly, and quick replacement

- Ability to operate intense cycles with low consumption and without performance degradation

- Compatibility with automation systems and centralized energy management

- Customization and industrial services

For specialized advice on selecting the most suitable electric fan motor for your industrial needs or for more information on our customized solutions, contact us now: our technical team is available to answer any questions and guide you in the ideal configuration for your system.

Served Industries and Competitive Advantages for Industry

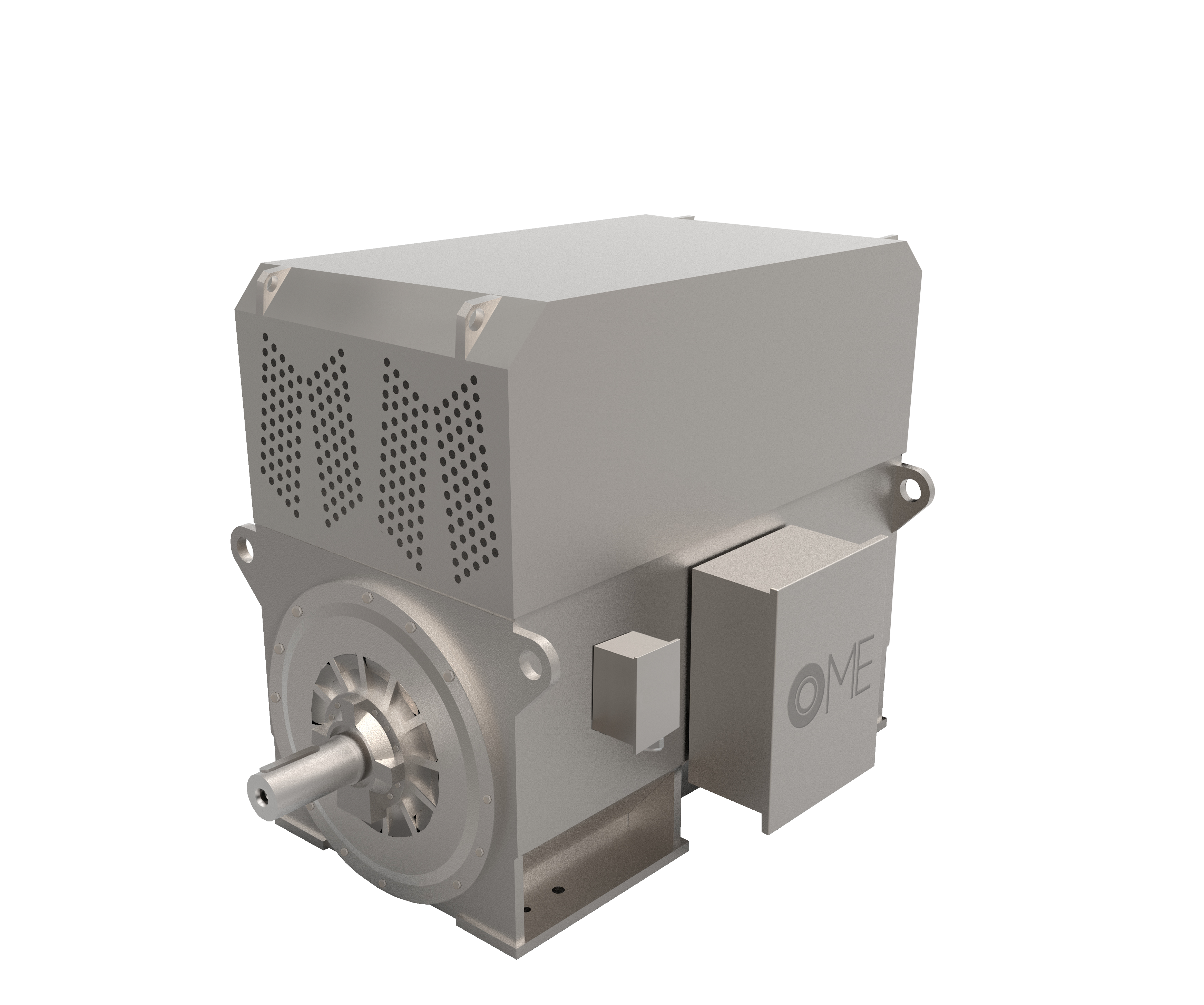

Our fan motors are designed and selected to meet the needs of:

Steel mills, paper mills, chemical and pharmaceutical industries, food & beverage, large-scale automation. Workshops and production departments where machines operate continuously, and ventilation is crucial for safety. automated warehouses, logistics areas, technical rooms, and industrial server farms.

The advantages of choosing a high-quality industrial fan motor translate into:

- Long-term savings on energy consumption

- Continuous reliability, with a drastic reduction in failures and replacements

- Possibility for remote monitoring and intelligent control in line with Industry 4.0

In the industrial sector, choosing the right fan motor guarantees productivity, safety, and energy savings. Investing in electric motors for fans designed for harsh environments means preventing production downtime, facilitating business growth, and ensuring optimal working conditions for operators. Discover the entire range dedicated to industry on our website, request a tailored consultation, and upgrade your systems with the assurance of relying on industry professionals.

![]()