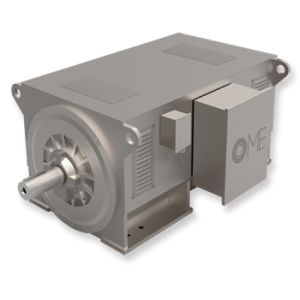

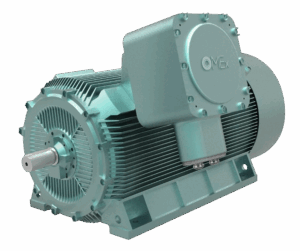

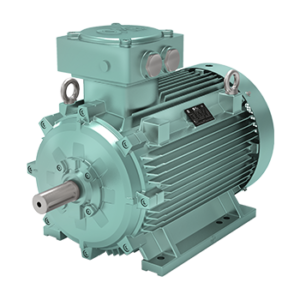

Motors for Machine Tools: A Variety of Solutions

In the world of machine tools, technical progress translates into an increasingly wide and articulated range of available motors. We find different solutions related to precision requirements, energy efficiency, and speed of movement.

Electric Motors for Machine Tools

The most common and versatile solution. A modern electric motor for machine tools is designed to provide:

- Precise speed control thanks to advanced electronic control

- Optimized consumption due to high efficiency, even in production environments operating 24/7

- Compatibility with modern CNC systems and Industry 4.0 platforms

- Reduced maintenance, long lifespan, and reliability in demanding conditions

The most interesting innovation in recent years, especially for applications that require is that technologies allow compliance with the demands of increasingly customization-oriented sectors, micro-machining, and the production of small batches with high variability.

- High-speed movements with minimal inertia

- Maximum positioning precision and constant repeatability

- Elimination of intermediate mechanical transmissions, resulting in reduced wear and noise

- Greater design freedom in machinery design and unconventional machining processes

When to Choose Motors for Machine Tools

Motors for machine tools represent the ideal solution, especially in contexts where:

- Simultaneous machining on multiple axes with millimetric synchronization

- Rapid direction changes (“play-free reversal”)

- Elimination of mechanical play and positional return

Sectors such as high precision, optical or medical component production, and microelectronics greatly benefit from the performance achievable with these solutions.

Application Areas

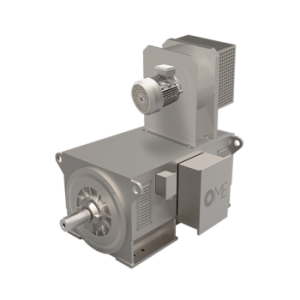

The choice of motors for machine tools must be guided by a careful evaluation of process specifications and actual production needs. Each industrial sector presents different key factors: types of machining to be performed (turning, milling, grinding, electro-erosion), required power and torque levels, positioning precision demands, machine footprint, and the degree of integration with advanced automation systems.

Our electric motors are designed to effectively meet the challenges of sectors such as:

- Precision mechanics and automotive, where speed, surface quality, and tight tolerances are essential

- Aerospace industry and optical production, with complex machining and technologically advanced materials

- Mold production, plastic processing, and the creation of special equipment, where customization and versatility are crucial

The modularity of our offering allows us to meet the needs of both small artisanal workshops and large industrial groups, providing solutions that combine technology, efficiency, and reliability across all production scales.

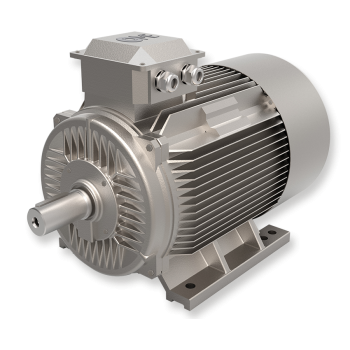

Economic and Productive Advantages of Technological Upgrades

A targeted upgrade of motors for machine tools produces:

- Increased productivity per unit of time

- Reduced machine downtime on an annual basis

- Lower energy consumption and reduced overheating in production environments

- Increased operational safety through advanced digital controls

- Improved quality of the finished product by reducing inaccuracies and defects due to mechanical play or premature wear

- Support, maintenance, and training

Innovation and operational efficiency start with the quality of key components. Choosing electric motors for machine tools from OME Motors from our catalog means investing in reliability, safety, and competitiveness for the future. Explore the range of electric motors and trust in the expertise of a team dedicated to the real growth of your business. From sizing to commissioning, we guarantee concrete, measurable, and lasting results

![]()