![]()

- About us

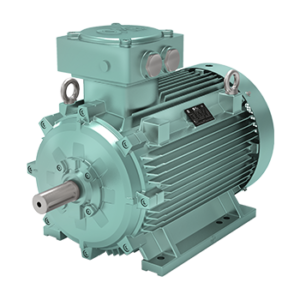

- Electric MotorsOME Motors progetta e realizza motori elettrici asincroni trifase, realizzati in alluminio oppure in ghisa. Tutti i motori elettrici di OME Motors rispettano i più alti standard qualitativi, garantiti da un efficace controllo effettuato direttamente dai tecnici dell’azienda; essi, inoltre, sono realizzati nel rispetto delle norme europee UNEL MEC che stabiliscono parametri universali a cui attenersi per la definizione di particolari costruttivi.

-

-

- Explosion-Proof Motors

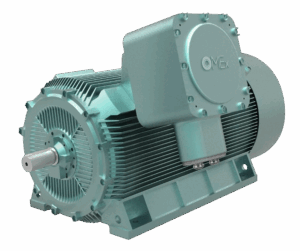

- High Voltage Motors and Medium Voltage Motors

- Smoke extraction motors

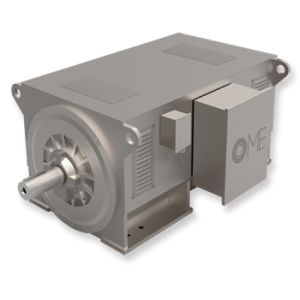

- Permanent Magnet Motors

- Standard motors

- Slip Ring Motors OMA High Voltage

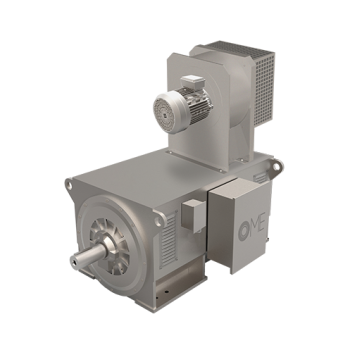

- DC Motors | OMDC

- NEMA Motors

- OMNEX Explosion Proof Nema

- Single Phase Motors

- Synchronous generators

- UL/CSA Electric Motors

- GOST Motors

-

- Explosion-Proof Motors

- High Voltage Motors and Medium Voltage Motors

- Smoke extraction motors

- Permanent Magnet Motors

- Standard motors

- Slip Ring Motors OMA High Voltage

- DC Motors | OMDC

- NEMA Motors

- OMNEX Explosion Proof Nema

- Single Phase Motors

- Synchronous generators

- UL/CSA Electric Motors

- GOST Motors

-

-

- Products

-

- Applications

- Service networks

- Blog

- Contacts

- Request information